Our Process

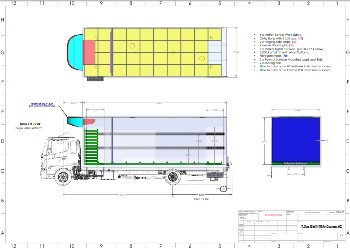

1. Design Process

Automated NZ provide technical assistance to bring your delivery vehicle concepts to life. We know what works and the right questions to ask to ensure you have a design that’s compatiable with your workflow and logistical requirements.

2. Panel Fabrication

Automated’s European partner turns your concept into reality! Every build bespoke, producing premium isothermal sandwich panel complete with the door frames and LED lighting in the positions that you require them in!

3. Shipping

Your truck body kit CKD (complete, knocked down) is then flat packed into a container for shipping to Automated’s engineering facility in Mount Maunganui, NZ

4. Build/ Assembly Process

Our team of Assembly technicians commence the build process, bringing your concept to life! A quality control checklist is followed throughout the build to ensure every detail is executed to an excellent standard.Attention to detail is critical to ensure that your box body has maximum strength and rigidity. Afterall, your delivery vehicle needs to work as hard as you do.Your cab chassis is prepped. Our team fabricate a subframe that will secure your box body to the chassis. Mudguards, reversing cameras and electrical features are also fitted during this process.

5. Truck Access Points

Once your body is secured to its chassis we then fit steps and bumpers. Automated can fabricate a number of configurations - hoop steps, fold out stairs, ladders and platforms.

6. Tail Lifts and platforms

Tail lifts are added at this point (if this was a feature you stipulated at the initial design stage). Cantilever Tail Lift platforms can also become rear doors.

7. The Complete Package

Your truck is ready for the refrigeration installation and sign writing!